Product Description

Product Description

|

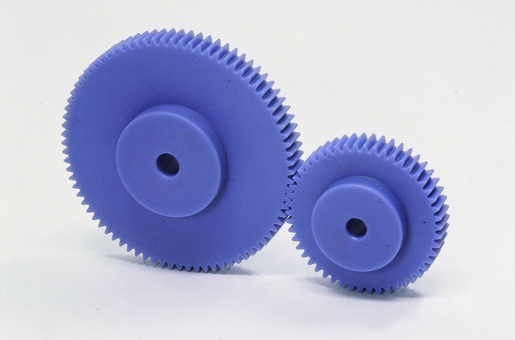

Name |

agriculture machinery parts grain drill 16×4.5 inch planter gauge wheels |

||

|

Size |

16×4.5 |

||

|

Type of tyre |

semi pneumatic type |

||

|

Feature and advantage |

It is easy to make the soil and mud fall off. It is lighter, better elasticity and antifriction than the CHINAMFG tyre; comparing to pneumatic tyre, it doesn’t need inflation and mend. |

||

|

Overall diameter |

16 inch |

||

|

Section width |

4.5 inch |

||

|

Rim |

steel spokes rim |

||

|

Color of rim |

black color. And we can produce any color according to your request. |

||

|

Surface treatment of rim |

powder coated |

||

|

Bearing |

5203KYY2 |

||

|

Application |

planters, seeders, grain drills, cultivators, grain augers, other agricultural machines, farming machines, etc. |

||

Company Profile

We are a comprehensive enterprise specializing in the research and development, design, and manufacturing of various types of agricultural machinery, logging machinery, tunnel machinery, engineering machinery, and mining machinery wear-resistant parts. With a construction area of 18500 square CHINAMFG and more than 150 employees, our annual export value exceeds 15 million US dollars. Our products are exported to multiple overseas markets such as Russia, the United States, Canada, Germany, Spain, the United Kingdom, and Australia.

HangZhou Guanxuan is a professional manufacturer of rubber connectors, rubber rollers, and conveyor chain assemblies for agricultural machinery; Rubber parts for construction machinery; There are nearly a thousand specifications of products such as water treatment equipment and rubber parts. We provide rubber products to large domestic enterprises and research institutions year-round, and some of our products have been exported to overseas markets such as Russia, the United States, Canada, Germany, Spain, the United Kingdom, and Australia.

Our main products include agricultural machinery flipping plow replacement parts, forestry logging tree pressure blade heads, planer pile cutting teeth, tunneling machine cutting heads, engineering machinery excavator bucket teeth, milling cutting teeth, blades, track pins, CHINAMFG buckets, high chromium chocolate, tunnel and mining machinery shield machine rollers, rotary excavator hard alloy engineering tools, rotary excavator alloy drill bits, petroleum survey drill bits, drilling hard alloy drill bit rubber joints, rubber rollers, conveyor chain assemblies, engineering machinery rubber parts, water treatment equipment rubber parts, and nearly a thousand other products.

Packing & Delivery

Certifications

The qualification certification we have obtained is based on our outstanding performance in the industry, as well as our commitment to customer service and product quality. This certification proves our leading position in the industry and confirms the authenticity and reliability of our commitment.

FAQ

Q1:what kind of products do you offer?

QA:We specialize in the design and production of agricultural machinery flip plow replacement parts and hard alloy deep loosening plow replacement wear-resistant parts, forestry logging tree pressure cutting head, planer pile cutting teeth, tunneling machine cutting head, engineering machinery excavator bucket teeth, milling cutting teeth, blades, track pins, CHINAMFG buckets, high chromium chocolate, tunnel and mining machinery shield tunneling machine rollers, rotary excavators hard alloy engineering tools.

Q2: What is the delivery cycle?

QA:For inventory, we need about 7 days and then deliver after inspection.

For ordinary G E. We need 15-45 days to produce T parts according to the current production plan, quantity, and product type.

For customized products, we need 15 days for mold opening, 7 days for sample testing, and then arrange production. A total of 45-60 days.

Q3: How long does it take to quote?

QA:After receiving detailed information, we will provide you with a quotation within 24 hours.

Q4. How is the quality?

QA:We can produce according to customer requirements, such as chemical composition, and then provide test reports for approval.

Our main markets are Russia, Australia, Europe, and the United States. The quality of charitable organizations is at a mid to high end level.

Q5: How about the warranty?

QA:If any of these parts are damaged under normal working conditions, we will still provide new parts free of charge.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Planter Part |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying |

| Material: | Rubber |

| Power Source: | Diesel |

| Weight: | 2lbs |

| After-sales Service: | Have |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you provide examples of products or machinery that commonly use plastic wheels?

Plastic wheels are used in a wide range of products and machinery across various industries due to their versatility and unique qualities. Here are examples of products and machinery that commonly use plastic wheels:

- 1. Office Furniture: Office chairs often feature plastic caster wheels for smooth and quiet movement on office floors.

- 2. Material Handling Equipment: Hand trucks, dollies, and carts used in warehouses and distribution centers frequently use plastic wheels to transport goods efficiently.

- 3. Lawn and Garden Equipment: Lawnmowers, garden carts, and wheelbarrows are equipped with plastic wheels for easy maneuverability on lawns and uneven terrain.

- 4. Retail and Shopping Carts: Shopping carts in supermarkets and retail stores typically have plastic wheels for easy navigation through aisles.

- 5. Medical Equipment: Hospital beds, medical carts, and mobility aids often incorporate plastic wheels, as they are easy to clean and resist corrosion.

- 6. Aerospace Ground Support: Ground support equipment at airports, including baggage carts and maintenance vehicles, may use plastic wheels for their lightweight properties.

- 7. Food and Beverage Handling: Food service equipment, such as serving trolleys and food processing machinery, often feature plastic wheels due to their resistance to moisture and corrosion.

- 8. Recreational Vehicles (RVs): RV leveling jacks and stabilizers utilize plastic wheels to provide stability and ease of adjustment when parked.

- 9. DIY and Home Improvement Tools: Hand trucks, utility carts, and toolboxes used for DIY and home improvement projects may have plastic wheels for ease of movement.

- 10. Industrial Machinery: Some industrial machines and equipment incorporate plastic wheels to facilitate movement and protect factory floors.

- 11. Conveyor Systems: Conveyor systems in manufacturing and logistics often use plastic wheels to support the movement of goods along production lines.

- 12. Skateboards and Skateboarding Equipment: Skateboard wheels are typically made of plastic, offering various sizes and hardness levels to suit different riding styles.

- 13. Boat Trailer Rollers: Rollers on boat trailers are commonly made of plastic, as they resist corrosion when exposed to water and provide smooth boat launching and retrieval.

- 14. Gate Hardware: Some gate wheels and sliding door systems feature plastic wheels for smooth operation and reduced noise.

These examples demonstrate the widespread use of plastic wheels in diverse applications, emphasizing their adaptability and suitability for various industries and products.

Can you provide insights into the importance of proper installation and alignment of plastic wheels?

The proper installation and alignment of plastic wheels are crucial for ensuring optimal performance, safety, and longevity in various applications. Here are key insights into their importance:

- 1. Load Distribution: Correct installation ensures that the weight load is evenly distributed across all wheels. Proper weight distribution prevents overloading of individual wheels, reducing the risk of premature wear and potential wheel failure.

- 2. Reduced Friction: Properly aligned wheels minimize friction and rolling resistance. Misalignment can result in increased friction, requiring more effort to move equipment or objects. This can lead to reduced efficiency and increased wear on the wheels.

- 3. Improved Maneuverability: Properly aligned wheels provide better maneuverability and control. Whether in industrial settings or everyday use, aligned wheels allow for smooth and precise movement, enhancing productivity and safety.

- 4. Floor Protection: Aligning wheels correctly helps protect flooring surfaces. Misaligned or unevenly loaded wheels can cause floor damage, such as scuffs, scratches, or dents, which can be costly to repair.

- 5. Enhanced Stability: Proper alignment contributes to the stability of equipment and vehicles. Misaligned wheels can result in wobbling or instability, posing safety hazards and potentially causing accidents or damage.

- 6. Longevity: Proper installation and alignment extend the service life of plastic wheels. Misalignment can lead to uneven wear, reducing the lifespan of the wheels and necessitating premature replacements.

- 7. Noise Reduction: Misaligned wheels can generate noise due to uneven rolling. Proper alignment minimizes noise pollution, making plastic wheels suitable for applications where quiet operation is essential.

- 8. Safety: Ensuring that wheels are correctly installed and aligned is crucial for safety. Misalignment or improper installation can lead to accidents, equipment failure, and injuries, especially in industrial and automotive settings.

- 9. Maintenance Efficiency: Properly aligned wheels are easier to maintain. Routine inspections and maintenance tasks are more straightforward when wheels are aligned, reducing downtime and maintenance costs.

- 10. Performance Consistency: Correct alignment results in consistent performance. This is essential for applications where precision and repeatability are critical, such as conveyor systems or automated machinery.

In summary, proper installation and alignment of plastic wheels are fundamental to their functionality and performance. They contribute to load distribution, reduced friction, improved maneuverability, floor protection, stability, longevity, noise reduction, safety, maintenance efficiency, and performance consistency. Neglecting alignment can lead to various issues that impact efficiency, safety, and the overall quality of operations.

Can you explain the primary functions and applications of plastic wheels in various industries?

Plastic wheels serve essential functions in various industries due to their unique properties and versatility. Here are the primary functions and applications of plastic wheels in different industries:

- 1. Material Handling: Plastic wheels are widely used in material handling equipment, including carts, dollies, and conveyor systems. They provide smooth and noiseless movement, making them suitable for transporting goods in warehouses, factories, and distribution centers.

- 2. Office Furniture: Plastic wheels are commonly found on office chairs and furniture. They allow for easy mobility, quiet operation, and floor protection. These wheels are often made from soft materials like polyurethane to prevent damage to flooring.

- 3. Automotive: In the automotive industry, plastic wheels are used for various applications, including caster wheels on tool carts, wheels for automotive jacks, and even lightweight spare tire wheels. They offer a balance of durability, weight savings, and cost-effectiveness.

- 4. Retail and Shopping Carts: Plastic wheels are a staple in retail and shopping cart applications. They provide smooth and silent movement for shoppers while navigating stores. The lightweight nature of plastic wheels reduces cart weight, making them easier to push.

- 5. Medical Equipment: Plastic wheels are used in medical equipment, such as hospital carts and medical devices. Their non-corrosive properties, lightweight design, and ease of cleaning make them suitable for healthcare settings.

- 6. Aerospace: In the aerospace industry, plastic wheels are used in ground support equipment, maintenance carts, and aircraft cabin service carts. Their lightweight construction is advantageous for handling equipment around aircraft.

- 7. Food and Beverage: Plastic wheels are found in food service equipment, including food carts, serving trolleys, and food processing machinery. They are resistant to moisture and corrosion, which is critical in food handling environments.

- 8. Recreational Vehicles (RVs) and Trailers: Plastic wheels are used in RV leveling jacks and trailer jacks. They provide stability and easy adjustment for leveling RVs and trailers when parked.

- 9. DIY and Home Improvement: Plastic wheels are used in DIY projects and home improvement applications. They can be found on hand trucks, utility carts, and DIY furniture, offering ease of movement and floor protection.

- 10. Marine and Boating: Plastic wheels are used on boat trailers and marine equipment. They resist corrosion from saltwater exposure and offer buoyancy, making them ideal for marine applications.

- 11. Agriculture: In agriculture, plastic wheels are used on farm equipment, including wheelbarrows and agricultural carts. They provide durability and easy maneuverability in outdoor and rugged environments.

Plastic wheels are valued for their lightweight, corrosion resistance, cost-effectiveness, and adaptability across a wide range of industries. They play a vital role in improving mobility, efficiency, and performance in various applications.

editor by CX 2024-04-09